An enhanced version of the ApolloBVM designed by Rice University engineers has received Emergency Use Authorization (EUA) by the U.S. Food and Drug Administration as an emergency resuscitator for use during the COVID-19 pandemic.

The device, as further developed by the Houston manufacturer Stewart & Stevenson Healthcare Technologies LLC, a subsidiary of Kirby Corporation, is designed to deliver air to the lungs of adult patients who require ventilation while they await the availability of a full ventilator.

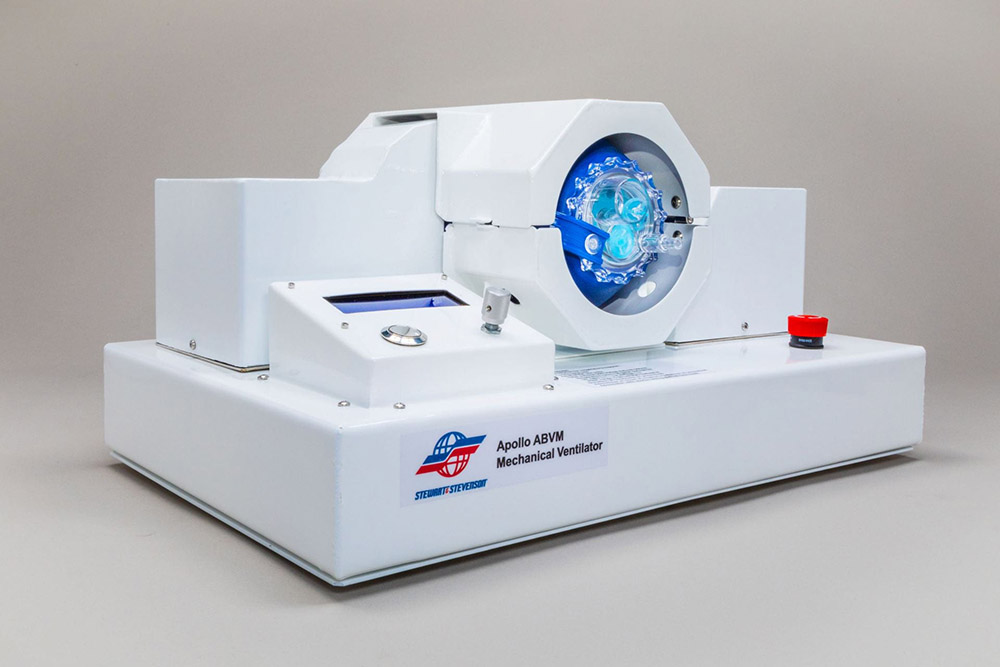

The manufactured version, dubbed Apollo ABVM, is a sturdy and portable system the company believes can be rapidly deployed in emergencies during the EUA period.

Rice Computer Science PhD student Thomas Herring led the development of the original control system and algorithm. “A lot of the work I do here as a student isn’t really applicable outside the classroom setting, so it’s really cool to work on a project where the effects are measurable in the number of lives it saves,” says Herring

Open-source plans for Rice’s ApolloBVM remain online and available to the maker community. The plans have been downloaded by nearly 3,000 registered participants in 115 countries.

Working around the clock for weeks, the small team, alone in the OEDK during the initial pandemic lockdown, toughened the device and added safety features for use in a medical setting, a process continued by Stewart & Stevenson, which licensed ApolloBVM in April.

The FDA authorization represents an important milestone achievement for the Apollo ABVM program,” said Joe Reniers, president of Kirby Distribution and Services. “We can now commence manufacturing and distribution of this low-cost device to the front lines, providing health care professionals with a sturdy and portable ventilation device for patients during the COVID-19 pandemic.”

Reniers said several manufacturing sites supported the effort, including manufacturing plants in Oklahoma City and Houston. “It is a testimony to the flexibility of our people and our manufacturing facilities that we are able to readily utilize operations to support COVID-19 related needs,” he said.

Mike Williams, Public Affairs